In today's digital age, where connectivity is the lifeline of businesses and individuals alike, optic fiber welding stands out as a cornerstone technology. It's the invisible thread weaving our world together, enabling seamless communication, lightning-fast data transfer, and the backbone of modern infrastructure. Let's delve into the intricacies of optic fiber welding and uncover why it's a game-changer in the realm of connectivity.

The Marvel of Optic Fiber Welding: A Fusion of Precision and Reliability

At its core, optic fiber welding is the process of joining two optical fibers end-to-end to allow light signals to pass with minimal loss. This delicate procedure demands precision, expertise, and state-of-the-art equipment. Unlike traditional welding techniques, optic fiber welding operates at a microscopic level, ensuring seamless connectivity without compromising signal integrity.

Unveiling the Benefits: Why Optic Fiber Welding Reigns Supreme

Minimal Signal Loss: Optic fiber welding facilitates a near-perfect connection, minimizing signal loss and ensuring maximum data transmission efficiency. Whether it's transmitting vast amounts of data or supporting critical communications, the reliability of optic fiber welding is unparalleled.

Enhanced Bandwidth: As our appetite for data grows exponentially, optic fiber welding provides a solution by offering unmatched bandwidth capabilities. It paves the way for high-speed internet, HD video streaming, cloud computing, and emerging technologies like virtual reality and the Internet of Things (IoT).

Longevity and Durability: Optic fiber welding creates robust connections that withstand environmental factors, vibrations, and fluctuations in temperature. This durability translates into reduced maintenance costs and prolonged service life, making it a cost-effective solution in the long run.

Flexibility and Scalability: Whether it's extending networks across vast distances or integrating new technologies, optic fiber welding offers unparalleled flexibility and scalability. Its modular nature allows for easy expansion and adaptation to evolving requirements, future-proofing your infrastructure investments.

Mastering the Art: The Optic Fiber Welding Process Demystified

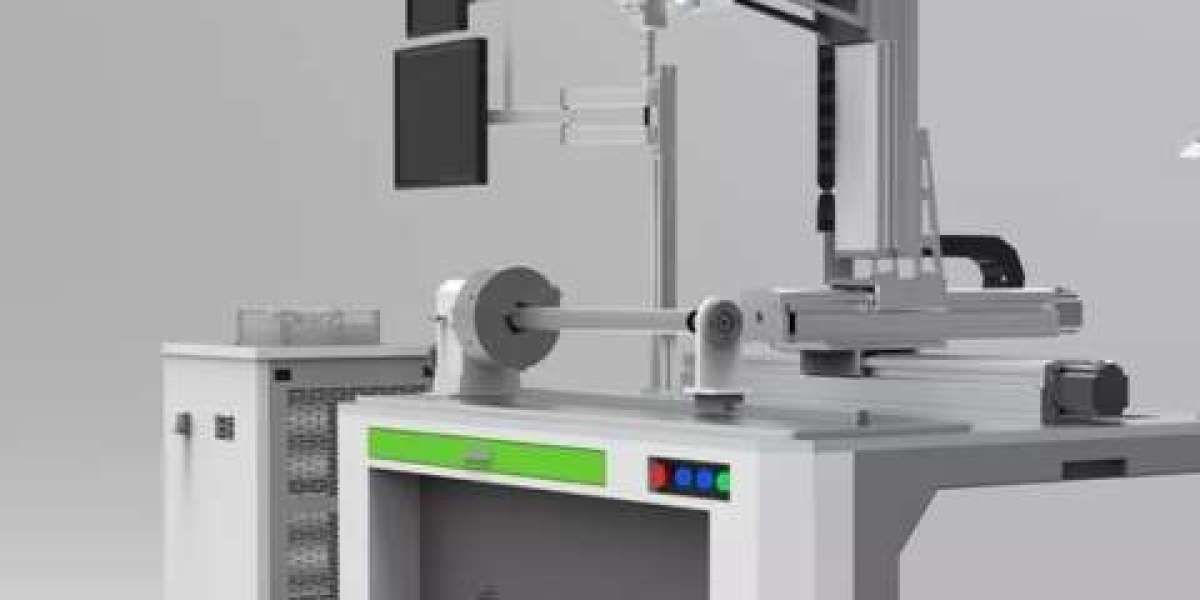

Optic fiber welding involves several precise steps to ensure a seamless connection:

- Fiber Preparation: The optical fibers undergo meticulous cleaning and stripping to remove impurities and coatings, ensuring pristine surfaces for welding.

- Alignment: The fibers are precisely aligned using specialized equipment to ensure optimal light transmission.

- Fusion Splicing: The aligned fibers are fused together using high-intensity heat, forming a seamless connection with minimal loss.

- Protection: A protective sleeve or coating is applied to the welded joint to safeguard it against external factors and maintain signal integrity.

Empowering Connectivity: Applications of Optic Fiber Welding

- Telecommunications: From global network backbones to local broadband connections, optic fiber welding forms the backbone of modern telecommunications infrastructure.

- Data Centers: Optic fiber welding enables high-speed data transfer within data centers, supporting cloud computing, big data analytics, and other mission-critical operations.

- Medical Imaging: In the field of medicine, optic fiber welding plays a crucial role in medical imaging systems, endoscopic procedures, and laser surgeries, ensuring precision and reliability.

- Industrial Automation: Optic fiber welding facilitates real-time monitoring, control, and automation in industrial settings, enhancing efficiency and productivity.

Conclusion: Unlocking Boundless Possibilities with Optic Fiber Welding

As we navigate the complexities of an increasingly connected world, optic fiber welding emerges as a beacon of reliability, efficiency, and innovation. Its ability to seamlessly transmit data across vast distances, its robustness in the face of challenges, and its versatility in various applications make it an indispensable technology shaping the future of connectivity. Embrace the power of optic fiber welding and unlock boundless possibilities in the digital age.