Composite Preforms Industry

Summary:

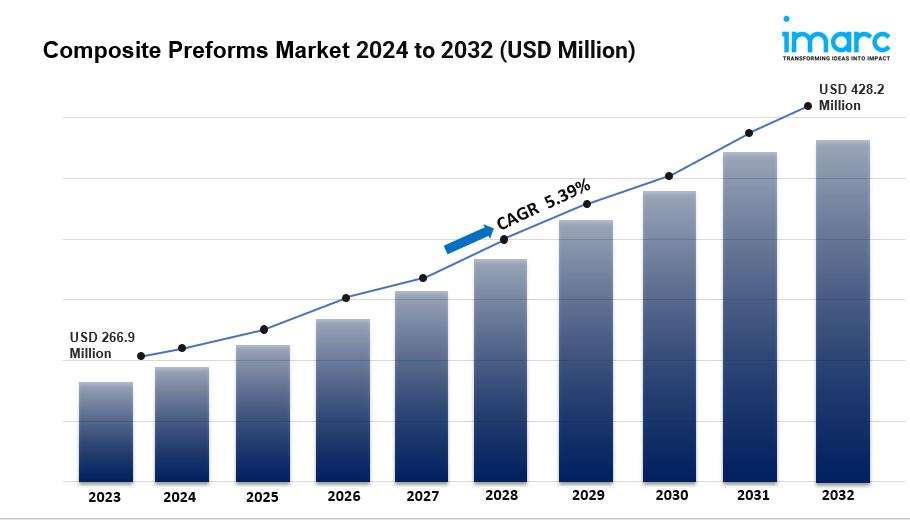

- The global composite preforms market size reached US$ 266.9 Million in 2023.

- The market is expected to reach US$ 428.2 Million by 2032, exhibiting a growth rate (CAGR) of 5.39% during 2024-2032.

- North America leads the market, accounting for the largest composite preforms market share.

- Based on the product type, the market has been categorized into stitching, braiding, knitting, and weaving.

- Carbon holds the largest share in the composite preforms industry, owing to the rising need for lightweight and durable materials.

- Aerospace and defense remain a dominant end use industry segment in the market, due to the increased defense budgets and growing commercial aviation.

- The growing need for lightweight materials in aerospace and automobile sectors is a primary driver of the composite preforms market.

- Rapid advancements and the introduction of three-dimensional (3D) printing technology are reshaping the composite preforms market.

- We explore the factors propelling the composite preforms market growth, including technological advancements, consumer behaviors, and regulatory changes.

Industry Trends and Drivers:

- Increasing Demand for Lightweight Materials in Aerospace and Automotive:

The rising demand for lightweight materials in industries like aerospace and automotive is one of the major factors boosting the market growth. Moreover, the growing focus on fuel efficiency, prompting manufacturers to seek ways to reduce vehicle and aircraft weight without compromising strength, is catalyzing the market growth. Additionally, the increasing adoption of composite preforms, which offer high strength-to-weight ratios, are fostering the market growth. Besides this, the heightened product demand in the aerospace industry to lower fuel consumption and improve performance for aircraft structures, including wings and fuselage components, is enhancing the market growth. Along with this, the rising focus of the automotive industry on reducing emissions and enhancing fuel efficiency in response to stricter environmental regulations is favoring the market growth.

- Growth in Wind Energy Installations:

The widespread demand for composite preforms in the wind energy sector due to the need for efficient, durable, and lightweight materials in turbine blades is acting as a growth-inducing factor. Along with this, the growing focus on renewable energy sources, leading to the construction of wind farms are being constructed is fueling the market growth. In line with this, the rising utilization of composite preforms in manufacturing turbine blades to withstand high stresses while maintaining lightness for optimal energy conversion is enhancing the market growth. Moreover, the long-term durability of composite preforms helps in reducing maintenance costs and extending the operational life of turbines, which is crucial for energy producers looking to maximize returns on investment.

- Rapid Advancements in Manufacturing Technologies:

The rising innovations like automated fiber placement (AFP) and automated tape laying (ATL) that improve the production efficiency of composite preforms, enabling mass production with high precision, are contributing to the market growth. These technologies reduce production time and labor costs, making composite preforms more accessible for a wide range of industries. Additionally, rapid advancements in three-dimensional (3D) printing technology that allows manufacturers to create more complex preform shapes, thus enhancing their application in industries like aerospace, automotive, and medical devices, is stimulating the market growth. Along with this, the heightened focus on lowering the overall cost of composite preforms, making them a more attractive option for small-scale and medium-sized enterprises, is supporting the market growth.

Request for a sample copy of this report: https://www.imarcgroup.com/composite-preforms-market/requestsample

Composite Preforms Market Report Segmentation:

Breakup By Product Type:

- Stitching

- Braiding

- Knitting

- Weaving

Based on the product type, the market has been divided into stitching, braiding, knitting, and weaving.

Breakup By Fiber Type:

- Carbon

- Glass

- Others

Carbon dominates the market as it offers superior strength-to-weight ratios and excellent stiffness.

Breakup By End Use Industry:

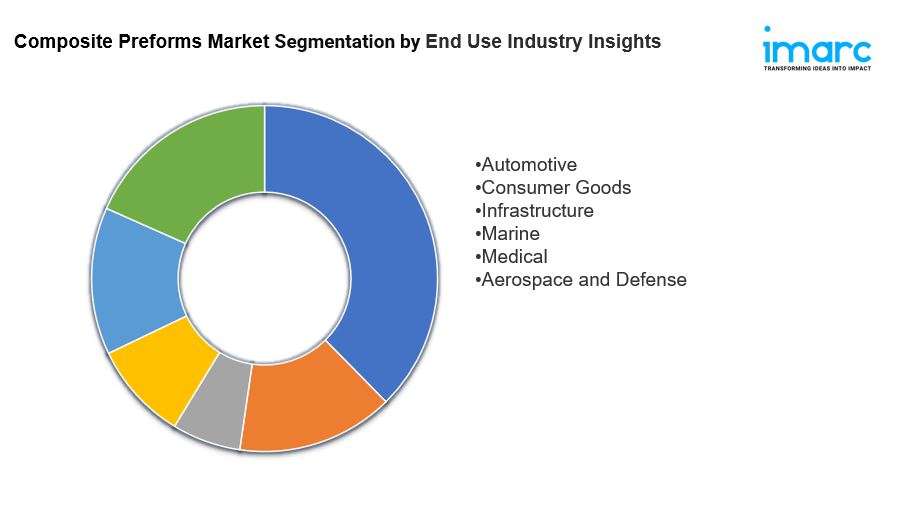

- Automotive

- Consumer Goods

- Infrastructure

- Marine

- Medical

- Aerospace and Defense

Aerospace and defense represent the majority of shares as they demand materials that provide high strength, low weight, and durability to improve fuel efficiency and performance.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America holds the leading position owing to a large market for composite preforms driven by the presence of leading aerospace and defense manufacturers, a well-established automotive industry, strong government investment in defense, and the availability of cutting-edge manufacturing technologies.

Top Composite Preforms Market Leaders:

The composite preforms market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies.

Some of the key players in the market are:

- A&P Technology Inc.

- Albany International Corp

- Axis Composites Limited

- Bally Ribbon Mills

- C & J Antich

- Eurocarbon B.V.

- Kümpers Composites (Kangde Composites Co., Ltd.)

- SAERTEX Group

- Sigmatex

- E.A.M. Inc.

Browse full report with TOC & List of Figures: https://www.imarcgroup.com/request?type=report&id=12643&flag=C

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.