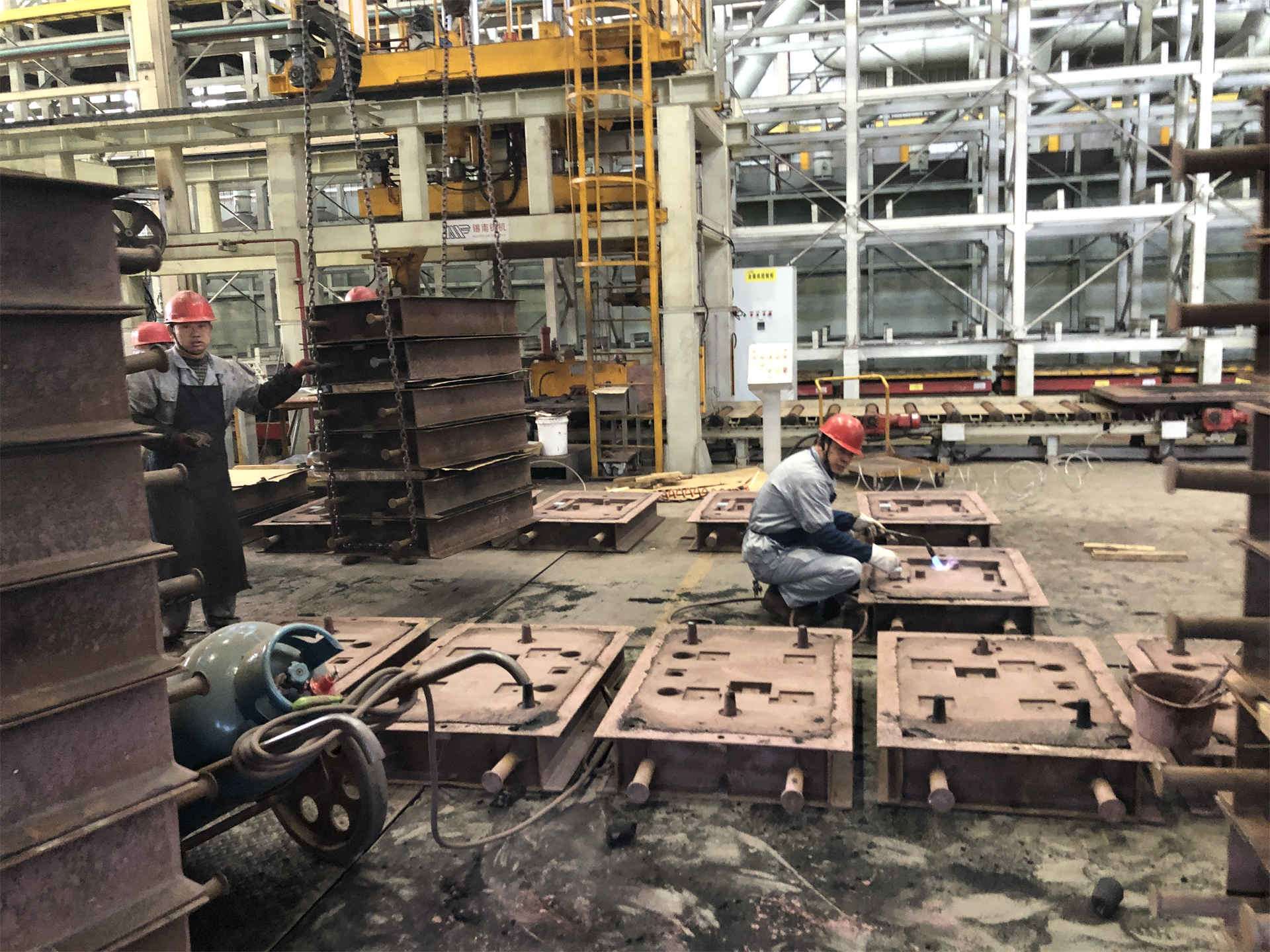

Experience the Precision and Versatility of sand casting

Are you looking for a reliable and cost-effective way to produce intricate and complex metal parts? Look no further than sand casting!

sand casting is a metal casting process that involves pouring molten metal into a mold made of sand. This versatile casting method allows for the production of parts and components with intricate designs, precise dimensions, and smooth finishes. Whether you need automotive parts, machinery components, or architectural elements, sand casting can help you bring your ideas to life.

One of the key advantages of sand casting is its ability to produce large and intricate parts. Unlike other casting methods, sand casting can create molds of any size and shape, making it ideal for manufacturing large components with complex geometries. This means that you can create parts with undercuts, recesses, and other intricate features that would be difficult or impossible to achieve with other casting methods.

Another advantage of sand casting is its flexibility. Sand molds can be easily modified and reused, allowing for the production of small batches or prototypes. This makes sand casting an excellent choice for design and development projects, as well as for custom and bespoke manufacturing.

In addition to its precision and versatility, sand casting is also known for its cost-effectiveness. The raw materials used in sand casting are relatively inexpensive, and the process itself is highly efficient. This makes sand casting an attractive option for businesses looking to reduce manufacturing costs while maintaining high quality.

Furthermore, sand casting offers a wide range of materials to choose from, including aluminum, brass, bronze, and iron. This allows you to select the material that best meets your specific needs, whether it's for corrosion resistance, strength, or aesthetic appeal.

In summary, sand casting is a reliable and cost-effective way to produce intricate and complex metal parts. Its precision, versatility, and material options make it an excellent choice for a wide range of applications, from automotive and machinery components to architectural and artistic elements. Discover the power of sand casting today and bring your manufacturing projects to life!