Summary:

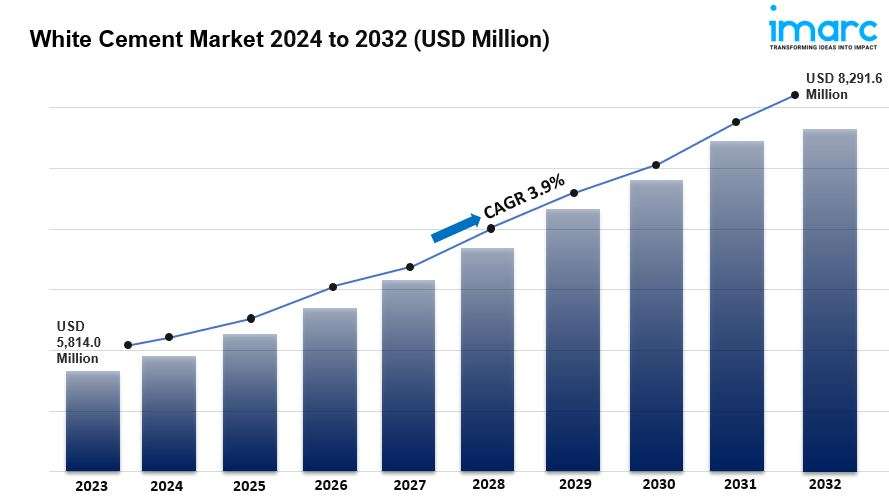

- The global white cement market size reached US$ 5,814.0 Million in 2023.

- The market is expected to reach US$ 8,291.6 Million by 2032, exhibiting a growth rate (CAGR) of 3.9% during 2024-2032.

- Asia Pacific leads the market, accounting for the largest white cement market share due to infrastructure development and rapid urbanization.

- White Portland cement accounts for the majority of the market share in the type segment due to its use in decorative and high-end architectural projects.

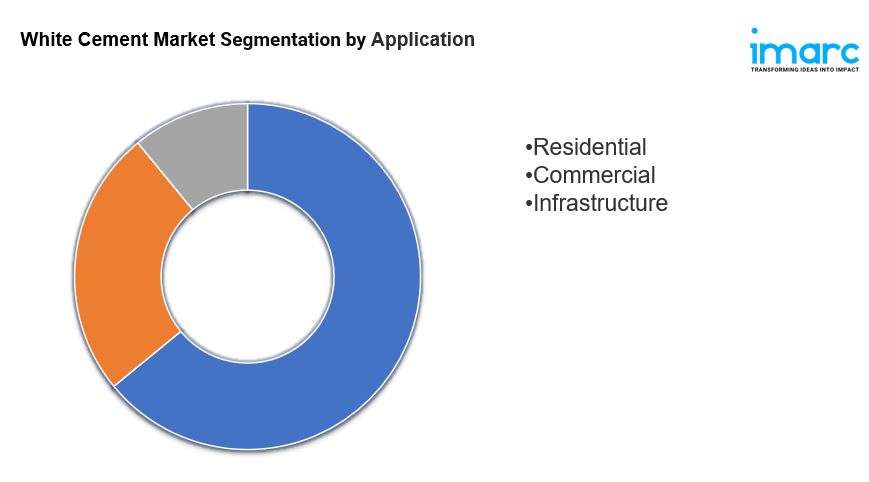

- Residential holds the largest share in the white cement industry due to the growing demand for aesthetically appealing housing.

- The aesthetic appeal of white cement is a primary driver of the white cement market.

- Rapid infrastructural development and increasing focus on sustainability are further reshaping the white cement market.

Industry Trends and Drivers:

Aesthetic and Decorative Applications: The aesthetic appeal of white cement is one of the major factors driving its demand in the construction sector. White cement’s ability to provide a smooth, bright, and uniform surface finish makes it an ideal material for decorative and architectural projects. Its brightness and color retention properties allow designers and architects to create visually striking structures, enhancing the overall appearance of buildings. Whether used for interior or exterior surfaces, white cement is a popular choice for decorative purposes, such as ornamental flooring, facades, and cladding. Additionally, the increasing focus on building design and aesthetic appeal in modern urban architecture is pushing developers and homeowners to opt for white cement over traditional gray cement. This preference is particularly evident in luxury residential and commercial projects, where the visual impact of the building is a top priority.

Growth in Infrastructure Development: Infrastructure development, particularly in emerging economies, plays a crucial role in driving the white cement market. Rapid urbanization and the expansion of smart city projectsare boosting the need for high-quality construction materials, including white cement. Governments in various regions are increasingly investing in infrastructure projects, including roads, bridges, residential complexes, and public buildings, all of which require durable and aesthetic materials. White cement is often used for creating durable structures that not only meet functional requirements but also offer a polished and clean finish. The growing focus on sustainability and energy-efficient building practices in large-scale infrastructure projects further increases the use of white cement, which is known for its lower environmental impact and energy efficiency.

Rise of Sustainable Construction Practices: The increasing focus on sustainable and environmentally friendly construction practices is significantly contributing to the growth of the white cement market. With stricter regulations on carbon emissions and a greater emphasis on eco-friendly building materials, white cement is being chosen for its lower environmental impact compared to gray cement. White cement production generates fewer emissions, as it typically requires lower energy consumption during the manufacturing process. In addition, white cement is often combined with supplementary materials such as fly ash or slag, which further reduces its carbon footprint. These characteristics align with the growing trend toward green building practices, where the use of sustainable and recyclable materials is a key focus. The incorporation of white cement into energy-efficient structures and eco-friendly designs is becoming more common, especially in regions where environmental regulations are stringent.

Request for a sample copy of this report: https://www.imarcgroup.com/white-cement-manufacturing-plant/requestsample

White Cement Market Report Segmentation:

Breakup By Type:

- White Portland Cement

- White Masonry Cement

- Others

White Portland cement accounts for the majority of shares due to its widespread use in high-end architectural and decorative projects, offering superior brightness and smooth finishes.

Breakup By Application:

- Residential

- Commercial

- Infrastructure

Residential dominates the market as the growing demand for aesthetically appealing housing and renovation projects drives the use of white cement in flooring, facades, and interior finishes.

Breakup By Region:

- Asia-Pacific

- Europe

- North America

- Latin America

- Middle East & Africa

Asia Pacific holds the leading position owing to rapid urbanization, infrastructure development, and rising construction activities in countries like China and India.

Top White Cement Market Leaders:

The white cement market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies.

Some of the key players in the market are:

- Cementir Holding N.V.

- Aditya Birla (UltraTech Cement Limited)

- JK Cement Ltd

- CEMEX

- Sotacib

- Ras Al Khaimah Cement Company

- Federal White Cement

- Saveh Cement Company

Browse full report with TOC & List of Figures: https://www.imarcgroup.com/white-cement-manufacturing-plant

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.