In any industrial setting, worker safety is paramount. Machinery and equipment, while crucial for productivity, can pose significant hazards if not properly controlled during maintenance and servicing. This is where Lockout-Tagout (LOTO) procedures come into play. LOTO is a set of standardized practices designed to prevent the accidental energization or startup of machinery while workers are performing maintenance or repairs. By effectively isolating hazardous energy sources, LOTO safeguards workers from serious injuries or fatalities.

This blog post will delve into the importance of LOTO in workplace safety, outlining its key benefits, the specific steps involved in the procedure, and the importance of proper training and documentation. We'll also explore the role of waterproof document holders in ensuring the accessibility and visibility of crucial LOTO procedures throughout the workplace.

Why is LOTO Important?

LOTO procedures are vital for several reasons:

- Preventing Accidents: By isolating hazardous energy sources such as electricity, hydraulics, pneumatics, and chemicals, LOTO significantly reduces the risk of accidents during maintenance activities. Accidental startups can lead to severe consequences, including electrocution, crushing injuries, and exposure to hazardous materials.

- Ensuring Regulatory Compliance: Many regulatory bodies, including the Occupational Safety and Health Administration (OSHA) in the United States, mandate the implementation of LOTO procedures in workplaces with hazardous energy sources. Following proper LOTO protocols ensures compliance with these regulations and avoids potential fines.

- Promoting a Culture of Safety: Effective LOTO implementation fosters a safety-conscious environment within the workplace. When workers see a strong commitment to LOTO protocols, they are more likely to prioritize their own safety and that of their colleagues.

The 6 Steps of a LOTO Procedure

LOTO procedures are a systematic approach to ensuring worker safety during maintenance. Here's a breakdown of the six essential steps involved:

- Preparation: Before commencing any work, the authorized worker must thoroughly understand the equipment and its energy sources. This involves reviewing technical manuals, identifying isolation points, and gathering the necessary LOTO devices (padlocks, tags, etc.).

- Shutdown: The equipment must be shut down using the appropriate controls, following established procedures.

- Isolation: Energy isolation devices like circuit breakers, valves, and blind flanges must be physically locked in the "off" position using appropriate LOTO devices. Only authorized workers should have access to these locks.

- Verification: Once isolation devices are locked, the authorized worker must verify that all hazardous energy sources are de-energized through testing or verification procedures outlined in the specific LOTO program.

- Work Execution: After successful verification, the authorized worker can safely proceed with maintenance or repair work.

- Removal of LOTO Devices: Following the completion of work, the authorized worker must follow established procedures for safely removing LOTO devices and re-energizing the equipment in the reverse order they were applied.

Training and Documentation: Cornerstones of Effective LOTO

For LOTO to be truly effective, comprehensive training and documentation are essential. Workers authorized to perform LOTO procedures must receive thorough training on the specific energy sources present in their work areas, the proper use of LOTO devices, and the steps involved in the procedure. This training should be documented and refreshed periodically, ensuring ongoing knowledge retention.

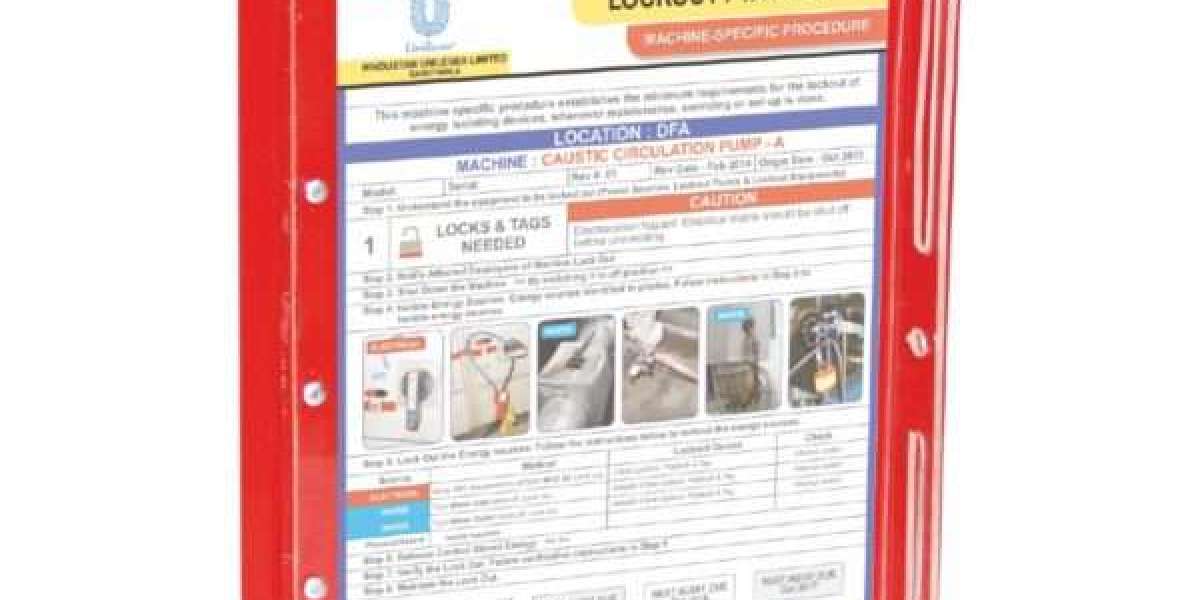

Waterproof document holders play a crucial role in maintaining readily accessible and legible LOTO procedures at all times. These holders protect vital LOTO documents, including program manuals, equipment-specific procedures, and energy isolation diagrams, from harsh workplace environments like moisture, dust, and chemicals. By keeping these documents readily available and clearly visible, waterproof document holders contribute significantly to worker safety and compliance.

Here are some additional resources for further information on LOTO:

- Occupational Safety and Health Administration (OSHA) Lockout/Tagout standard: https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.147

- The National Institute for Occupational Safety and Health (NIOSH) LOTO webpage: https://www.cdc.gov/niosh/docs/wp-solutions/2011-156/default.html

Conclusion

LOTO procedures are a cornerstone of industrial safety. By effectively isolating hazardous energy sources, LOTO safeguards workers from injury and promotes a safety-conscious environment. Implementing proper training, utilizing appropriate LOTO devices, and maintaining readily accessible documentation through waterproof document holders are all crucial for ensuring a successful LOTO program. Remember, investing in worker safety is an investment in your company's overall success.