In the fast-paced world of communication, where data transmission speed is king, optic fiber welding emerges as the unsung hero, silently revolutionizing the way we connect. With its unparalleled efficiency and reliability, optic fiber welding has become the cornerstone of modern telecommunications infrastructure, ensuring seamless connectivity across the globe.

The Science Behind Optic Fiber Welding

At its core, optic fiber welding is a precise and intricate process that involves joining two optical fibers to create a continuous path for light to travel. This seamless connection is crucial for maintaining the integrity of data transmission, as any disruption or loss of signal can lead to delays or even complete communication breakdowns.

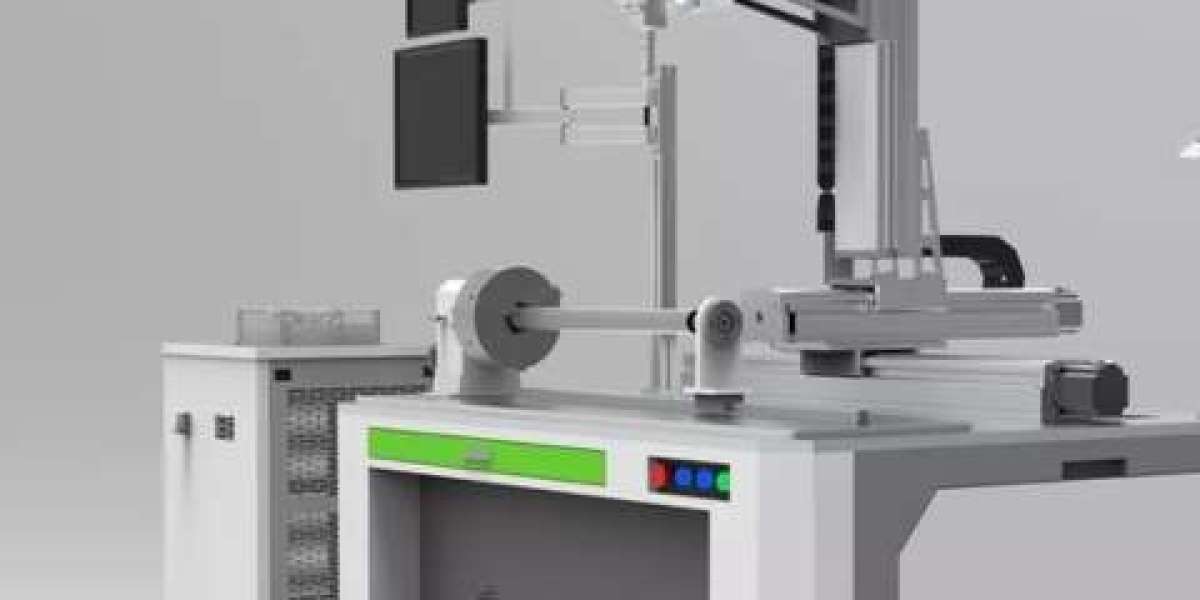

The process begins with the preparation of the optical fibers, where the protective coatings are carefully stripped away to expose the pristine glass underneath. Next, the fibers are precisely aligned using specialized equipment to ensure optimal connection efficiency. Once aligned, the fibers are fused together using high-intensity heat, creating a permanent bond that is virtually indistinguishable from the original fibers.

Unleashing the Power of Optic Fiber Welding

The benefits of optic fiber welding are manifold, ranging from enhanced data transmission speeds to increased reliability and durability. Unlike traditional copper cables, optic fibers are immune to electromagnetic interference and can transmit data over long distances without any loss of signal strength. This makes them ideal for powering the backbone of modern communication networks, including internet infrastructure, telecommunication systems, and data centers.

Furthermore, optic fiber welding enables the creation of intricate networks with virtually unlimited bandwidth capacity. This means that as our demand for data continues to grow exponentially, optic fiber welding ensures that our communication networks can keep pace with our ever-expanding needs.

Applications Across Industries

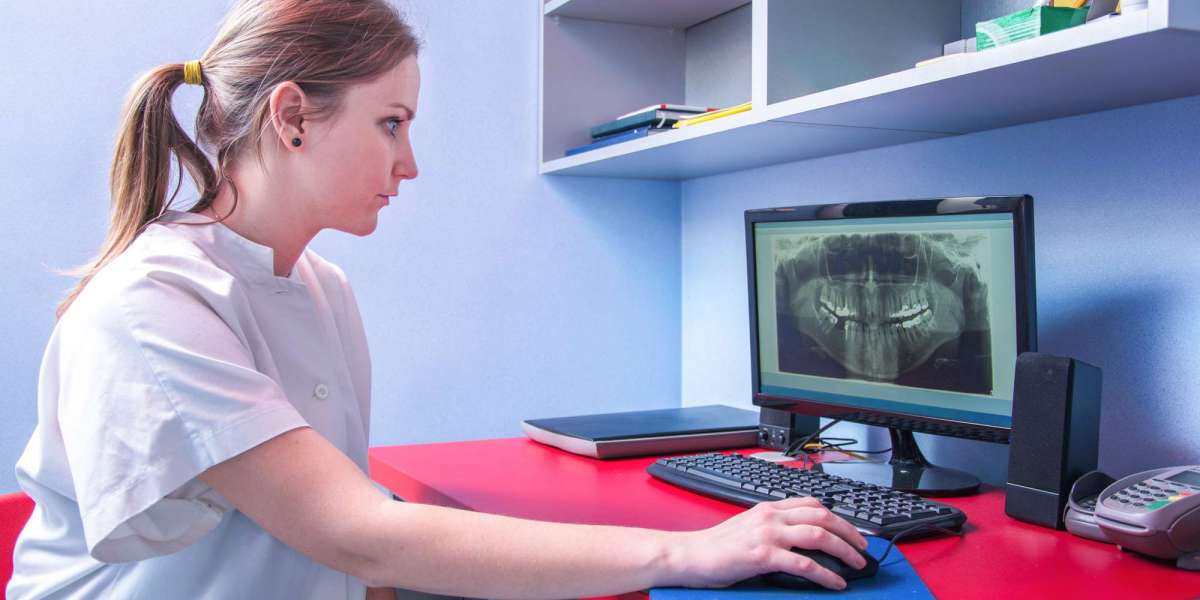

The versatility of optic fiber welding extends far beyond the realm of telecommunications, with applications spanning a wide range of industries. In the healthcare sector, optic fibers are used in medical imaging devices such as endoscopes and surgical lasers, enabling doctors to perform minimally invasive procedures with unparalleled precision.

In the manufacturing industry, optic fibers are utilized for quality control and inspection purposes, providing real-time feedback on production processes to ensure optimal efficiency and accuracy. Additionally, optic fiber sensors are increasingly being deployed in infrastructure monitoring systems to detect structural weaknesses and prevent potential disasters before they occur.

Embracing the Future of Connectivity

As we continue to push the boundaries of what is possible in the digital age, optic fiber welding will undoubtedly play a central role in shaping the future of connectivity. Its ability to deliver high-speed, reliable data transmission over vast distances makes it an indispensable tool for powering the technologies of tomorrow.

By embracing optic fiber welding, businesses can unlock new opportunities for innovation and growth, while consumers can enjoy seamless connectivity wherever they go. From streaming high-definition content to conducting remote medical consultations, optic fiber welding is paving the way for a future where distance is no longer a barrier to communication.

Conclusion

In conclusion, optic fiber welding represents the pinnacle of modern connectivity technology, offering unparalleled speed, reliability, and versatility across a wide range of applications. As we continue to embrace the digital revolution, optic fiber welding will undoubtedly remain at the forefront of innovation, driving progress and empowering the world to stay connected like never before.